Heavy Duty Sliding Gate Maintenance Checklist for Busy Sites

Heavy Duty Sliding Gate maintenance isn't optional for busy facilities - it keeps people safe, vehicles moving, and audits painless.

Why Maintenance Matters On Busy Sites?

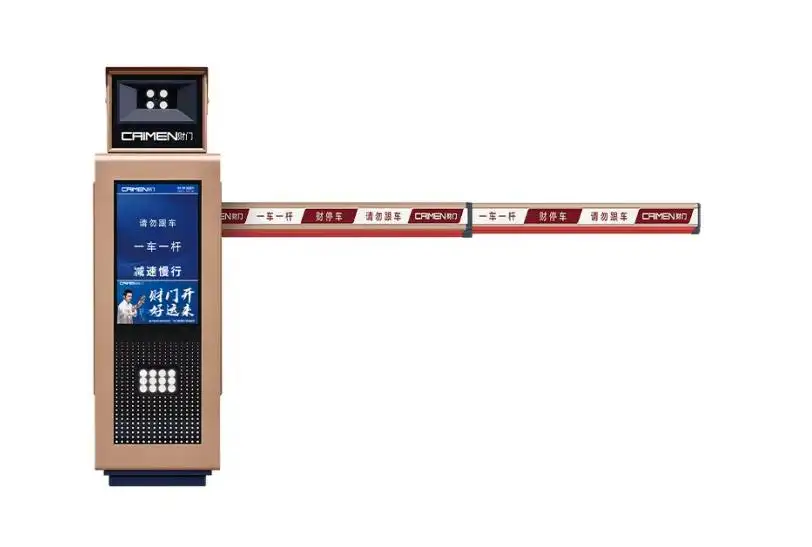

At CAIMEN, we watch high-traffic entrances minute by minute. Forklifts hurry, trucks idle, and shift changes compress thousands of movements into short windows. In that pressure, a Heavy Duty Sliding Gate does more than open and close; it protects people and assets while regulating flow. When upkeep slips, small defects become big costs: missed deliveries, damage claims, and compliance headaches.

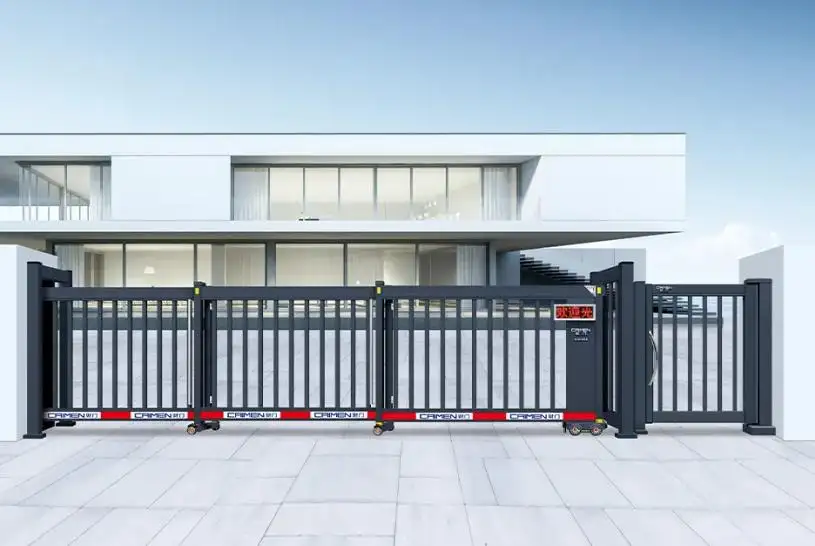

Our telescoping layout is designed for tight aprons and narrow driveways. Multiple panels stack into a compact footprint, so you avoid long runback or wide swing arcs. That space win is only valuable when motion stays smooth and true. CAIMEN builds for that reality: weather-resistant structures in galvanized steel or powder-coated aluminum, and either trackless or tracked formats to match your surface. For wind-exposed corridors, a wide 680-mm chassis increases stability, and a wind-resistant hook that mates cleanly with the track slot boosts resistance by up to eight times. The pay-off is consistent motion and fewer service calls - if you follow a disciplined care plan.

Lower friction by design. Nano-level wear-resistant wheels and all-cast aluminum hubs reduce rolling resistance and vibration. On trackless lines, magnetic scanning correction keeps the Heavy Duty Sliding Gate running straight, cutting side load and extending wheel and guide life. Fewer jolts mean fewer surprises for operators and fewer stoppages in your yard.

The Field-Tested Maintenance Checklist

This checklist suits industrial yards, logistics hubs, gated campuses, and perimeter-critical sites. Keep it practical, keep it visible, and keep the cadence.

✅ Weekly Essentials (5 - 10 Minutes)

• Walk-Around Inspection: Scan the Heavy Duty Sliding Gate body and panel joins for dents, loose fasteners, and early corrosion. Touch up coatings before rust spreads.

• Clean The Rolling Path: Clear gravel, shrink-wrap tails, mud, and leaves from track and wheel zones. Debris is the number-one cause of noise and slow starts.

• Photo-Eye Check: Pass a cone, pallet, or board through the beam while closing. The gate must stop and reverse immediately.

• Airbag Test: Lightly press the anti-collision airbag. The pressure wave should signal the main control board and halt motion at once.

• Listen Closely: Squeal, grind, or a new thump signals misalignment or wheel wear. Log the sound and location and investigate before failure.

✅ Monthly Reliability Tasks

• Alignment & Stack Accuracy: Confirm the telescoping panels stack squarely. If drift appears, recalibrate. Magnetic scanning should hold a straight run; if not, address guidance and fasteners.

• Targeted Lubrication: Apply the specified lubricant to hinges, pivots, and wheel bearings. Do not over-grease - excess attracts grit and accelerates wear.

• Electrical Integrity: Inspect CAIMEN's protected power-supply transmission: chain, stainless wire bracket, nylon protection wheels, and our 3-core 99.99% oxygen-free copper cable. Look for abrasion, looseness, or heat marks.

• Track & Hook Fit (If Tracked): Check the all-aluminum one-time-formed track or solid galvanized steel track (engineered to bear heavy vehicle loads) for deformation. Verify the hook-to-slot engagement that yields superior wind resistance.

• Control Diagnostics: Run a quick test on the 10th-generation digital integrated controller. Confirm soft starts, predictable braking, and clean links to remotes, keypads, and your access platform.

✅ Safety Functions You Must Verify

• Infrared Anti-Collision: Photo-eyes at each post must stop and auto-reverse on obstruction.

• Infrared Anti-Climbing: Ten seconds after closing, the top beam should alarm if anyone breaches the field.

• Emergency Stop: The red mushroom E-stop must cut power instantly and consistently.

• Anti-Pinch Response: Press the inner anti-pinch strip gently during motion; the gate should halt immediately.

• Event Logging: Save weekly test records. Good logs speed incident reviews and help insurers and auditors.

Tip for managers: Assign a named owner for each gate. Accountability beats "everyone's job,” and trends become visible faster when one set of eyes watches performance over time.

Built-In Advantages That Make Care Easier

Downtime is expensive. CAIMEN designs reduce it with components that are simple to check and resilient under heavy use.

- Motor & Drive: Strong Starts, Calm Stops

Our precision die-cast aluminum-alloy motor housing sheds heat efficiently. High starting torque handles frequent duty cycles typical of a Heavy Duty Sliding Gate at busy entries. An embedded thermal protector shields the windings, while reliable self-locking holds position against back-drive and tampering. If power fails, a manual clutch enables controlled hand movement. Cold is not a show-stopper: the system operates in low-temperature environments down to −35 °C, so winter shifts stay on schedule.

Seven built-in protections and behaviors extend service life:

• Frequency conversion adapts speed and reduces energy waste.

• Soft start limits inrush and mechanical shock to wheels and guides.

• Soft brake prevents jolts that shake fasteners loose.

• High-temperature protection guards against overheating under peak load.

• Motor self-locking resists forced movement when closed.

• Manual clutch keeps you operational during outages.

• Overload protection stops minor jams from becoming major repairs.

- Controls & Integration: Faster, Smarter, Safer

Our 10th-generation digital integrated control platform runs up to five times faster than the previous release, giving you crisp torque limits, smoother reversals, and quick pairing with modern access systems. That responsiveness matters when a truck cuts it close or a pedestrian hesitates. It also improves data: clean event logs help you prove maintenance diligence and reconstruct incidents without guesswork.

Safety power routing you can trust. The chain, stainless wire bracket (one-piece formed at high temperature), nylon protection wheels, and CAIMEN's oxygen-free copper conductors keep the supply secure and stable. The goal is simple: no disconnected wires, no cuts, no leaks - just predictable power to every sensor and actuator on the Heavy Duty Sliding Gate.

Trackless or tracked - your site decides. Trackless systems excel where grit, snow, or heavy debris would foul rails; the magnetic scanning correction keeps motion straight and reduces friction. Tracked systems shine on long, level runs and heavy yards; our solid steel or formed-aluminum rails and the matched wind-hook deliver dependable guidance under crosswinds.

✅ Quick Ways To Stretch Service Intervals

• Keep a laminated weekly/monthly checklist at the gatehouse and sign it off.

• Capture noise changes, weather events, and near-misses in a simple log; patterns reveal root causes.

• Schedule seasonal deep cleans after storms or construction.

• Stock common consumables - wipes, lubricant, fasteners, and spare photo-eyes - so small fixes happen fast.

About CAIMEN. CAIMEN is committed to providing high-quality intelligent entrance and exit solutions to global customers and continuing to lead the industry's development trend. We design every Heavy Duty Sliding Gate to be reliable in the field and straightforward to maintain - because real sites are busy, messy, and time-poor.

Call To Action - Talk To CAIMEN: If your Heavy Duty Sliding Gate handles peak traffic or harsh weather, ask us for a rapid reliability audit or a tailored upkeep plan. We'll help you cut noise, prevent unplanned stops, and keep people and cargo moving - day after day.

FACEBOOK

FACEBOOK

TWITTER

TWITTER

LINKEDIN

LINKEDIN