Choosing the Right Electric Fence Barrier Gate for Heavy Use

Choosing the Right Electric Fence Barrier Gate for heavy use is not just a hardware decision. It is an operations choice. The wrong gate slows traffic. It raises risk. It wastes space your site cannot spare. The right gate does the opposite. It clears lanes fast. It stays stable in wind and weather. It connects to your access control with ease. But how do you tell the difference on paper? What specs matter when trucks queue and minutes count? In the next section, we reveal the simple checks that separate reliable from risky - and the red flags most buyers miss.

Why An Electric Fence Barrier Gate Excels Under Pressure?

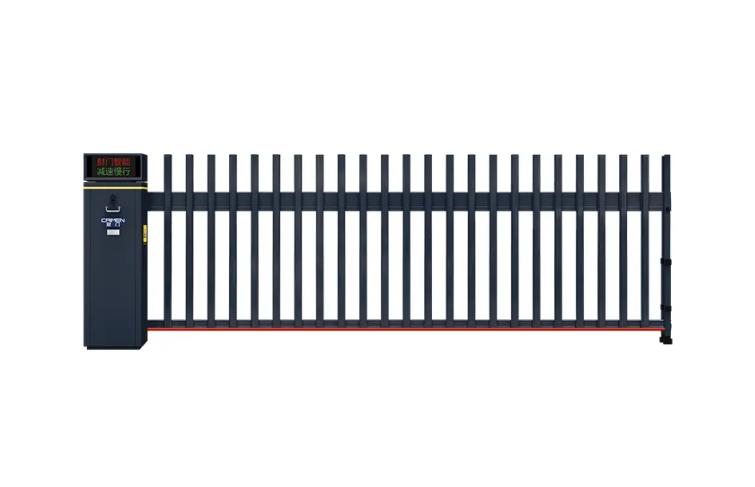

Heavy-use locations - logistics hubs, factories, data centers, airports - share the same reality: long queues cost money. An Electric Fence Barrier Gate rotates upward around a central pivot instead of traveling sideways on a track. That simple change delivers big operational gains.

Tight aprons, uneven ground, and wind are common headaches for sliding and swing gates. Tracks fill with gravel and ice. Swing arcs steal driveway width. By moving vertically, the gate keeps the lane clear and minimizes interference with trailers, forklifts, or emergency vehicles. It also reduces the chance of binding under crosswinds because there's no long horizontal span to rack or misalign.

Real-world pain points the vertical design helps solve include:

• Space Constraints: No wide swing arc and no long slide path to occupy scarce apron space.

• Weather Exposure: No ground track to clog with mud, snow, or debris.

• High Throughput: Faster open/close cycles keep vehicles flowing at peak times.

• Safety And Liability: Predictable motion with sensors lowers incident risk.

• Maintenance Burden: Fewer moving interfaces and sealed components cut service calls.

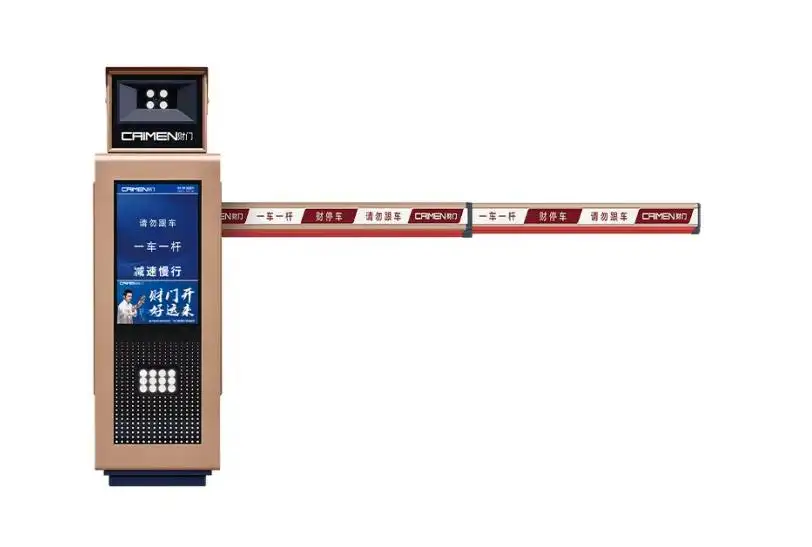

For sites that never sleep, consistency matters as much as speed. CAIMEN's Electric Fence Barrier Gate is built to operate smoothly shift after shift, then lock down securely when the lane must be sealed.

What To Look For When Specifying Heavy-Duty Performance

Buying on price alone is an easy way to overspend later. Match performance to the actual workload and environment. The right spec prevents early wear, nuisance faults, and unplanned downtime.

✅ Core Performance Criteria

• Duty Cycle And Speed: Choose automation sized for continuous, peak-hour activity. Soft-start and soft-stop profiles protect motors, pivots, and bearings.

• Safety Systems: Require anti-crush detection, automatic locking, and a fail-safe response to obstacles. The gate should stop or reverse in real time.

• Access Control Integration: Confirm compatibility with mobile apps, keypads, RFID, and biometrics. Video and event logs support audits and compliance.

• Weather And Wind Resistance: Look for sealed electronics, protected wiring, and frames engineered to hold alignment under gusts.

• Space Efficiency: Vertical pivot motion saves driveway width and keeps staging areas open, even with wide vehicles or tight turning radii.

- Built For Demanding Environments

Material choice has a direct impact on lifespan. CAIMEN uses powder-coated steel, stainless steel, or aluminum to deliver strength while resisting corrosion and wear. Housings are sealed against dust and water. Fasteners and hinges are specified for outdoor duty. These details extend service intervals and keep performance consistent across seasons.

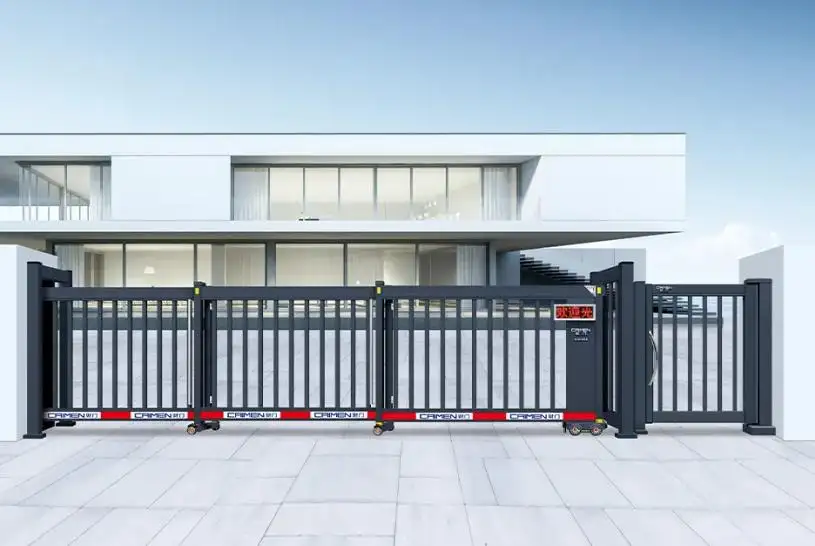

- Customization And Aesthetics

Security hardware should fit the site, not fight it. CAIMEN offers customizable panels, privacy levels, and finishes so the gate can blend with contemporary architecture or present a strong visual barrier where needed. You can choose open designs for sightlines or solid infills for privacy and noise reduction - without changing the core mechanics of the Electric Fence Barrier Gate.

- Integration And Control

Modern facilities depend on connected systems. CAIMEN's platform links the Electric Fence Barrier Gate to VMS/CCTV, visitor management, and building systems. You can set time-based rules, remote authorizations, and two-factor entry for sensitive zones. Dashboards display live status, alarms, and cycle counts so maintenance can be scheduled before issues escalate.

CAIMEN's Approach

A gate that "mostly works” is expensive. Driver delays add labor and fuel costs. Technicians on call drain budgets. CAIMEN designs every Electric Fence Barrier Gate for uptime first, then reduces lifetime cost with materials, controls, and serviceability that simplify ownership.

- Engineering For Uptime

Inside the control cabinet, advanced automation manages motion precisely. Components are sized for industrial duty cycles, not occasional use. Cable routing and access panels are planned so technicians can reach service points quickly. Clear diagnostics shorten troubleshooting. When maintenance is fast, operations stay on schedule.

- Security Without Friction

Security should protect people and assets without slowing business. CAIMEN gates support multi-layer authentication - from RFID and PINs to biometrics - while keeping entry fast for authorized vehicles. Automatic locking hardens the perimeter the moment the leaf lowers. Pair the gate with cameras to capture plates and credentials, then reconcile those events with your access logs.

✅ Where An Electric Fence Barrier Gate Fits Best

Use cases vary, but the same principles apply:

• Commercial And Industrial Sites: Rapid cycling handles deliveries, shift changes, and contractor traffic without creating choke points.

• High-Security Access Points: Consistent locking, detailed event history, and integration with alarms create a layered defense.

• Gated Communities And Estates: Modern lines and quiet operation deliver strong security with a refined look.

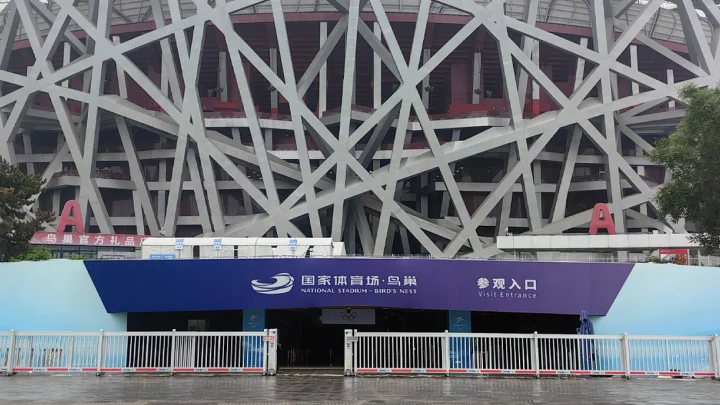

• Airports And Government Facilities: Reliable automation and strict safety features meet regulated standards.

❓ Why It Lowers Total Cost Of Ownership?

Total cost of ownership is more than the purchase order. Space-efficient installation reduces civil work. Weather-resistant construction cuts repainting and part replacement. Predictable movement reduces shock loads and extends component life. With fewer track-related failures and fewer emergency calls, the Electric Fence Barrier Gate pays for itself in uptime and throughput.

✅ A Practical Selection Workflow

To translate needs into a reliable spec, follow this simple path:

• Map The Traffic: Count peak vehicles per hour and define acceptable wait times.

• Measure The Space: Confirm clearances, turning radii, and any grade changes.

• Assess The Climate: Plan for wind, snow, dust, and drainage at the threshold.

• Define The Risk Profile: Choose the level of authentication and video capture needed.

• Plan Maintenance: Align service intervals with your facility's maintenance windows.

CAIMEN's engineering team can turn those inputs into a tailored recommendation - material selection, safety devices, access integrations, and finishing options - so the final Electric Fence Barrier Gate matches your real operating conditions.

Call To Action

Ready to specify the right Electric Fence Barrier Gate for your heavy-use site? Contact CAIMEN to speak with an engineer about throughput targets, safety requirements, and system integration. We'll model duty cycles, recommend materials and finishes, and design a solution that suits your lane, climate, and budget - so your operation stays secure, fast, and future-ready.

FACEBOOK

FACEBOOK

TWITTER

TWITTER

LINKEDIN

LINKEDIN