Custom Sliding Gate Materials: Which Lasts Longest?

Choosing the right Custom Sliding Gate material decides how long your entrance works and how safe it stays. Aluminum, steel, wood, and composites each promise something. Some resist rust. Others carry heavy loads. A few look elegant but need care. What truly lasts in wind, salt, and daily cycles is not obvious. The secret sits in weight, coatings, tracks, and control. One choice cuts energy and repairs. Another fails within a season. In the pages below, we test the claims - and reveal the material that actually wins.

Material Performance And Real-World Aging

Different materials age in different ways. In long-running projects, the longest-lasting Custom Sliding Gate is the one that resists corrosion, holds alignment in strong winds, tolerates thermal swings, and keeps geometry and surface finish intact after countless cycles.

Aluminum Alloy (CAIMEN's Baseline Choice). Modern aluminum alloys deliver a rare mix: low mass, high stiffness, and excellent oxidation resistance. Lower weight eases the workload on motors, wheels, and tracks - reducing heat, vibration, and energy draw. When paired with a fluorocarbon powder coat and a two-stage drying/baking process, the finish resists chalking and discoloration even in coastal air or polluted urban settings. The result is slower wear on moving parts and longer intervals between service.

Galvanized Steel. Where extreme track strength is non-negotiable - yards with heavy vehicles, industrial bays, or mixed-freight entrances - steel remains the muscle. A solid galvanized steel track can support up to 120 tons of vehicle weight. The tradeoff is mass and the need for vigilant edge protection at welds and cuts to keep corrosion at bay.

Wood And Composites. These materials bring warmth and visual texture but demand more care. UV exposure, moisture, and temperature cycling can lead to warping or finish fatigue. For that reason, CAIMEN typically uses wood or composite as cladding over a metal frame, retaining the aesthetics while the structure remains metallic and stable.

What Typically Fails - And How To Avoid It?

Most "end-of-life” headaches stem not from the leaf itself, but from interfaces that move, sense, or protect.

• Wheels & Tracks - Wear, misalignment, and debris increase rolling resistance and motor temperature.

• Motors & Drives - Undersized units or poor heat dissipation shorten service life.

• Coatings & Seals - Micro-cracks invite corrosion that accelerates fatigue.

• Sensors & Cabling - Abrasion, loose connectors, or mis-aimed sensors cause false trips or unsafe states.

CAIMEN's answer is to lighten and stiffen the structure, specify nano-grade wear-resistant wheels, protect cables with stainless brackets and nylon guide wheels, and keep alignment true so components experience less stress per cycle.

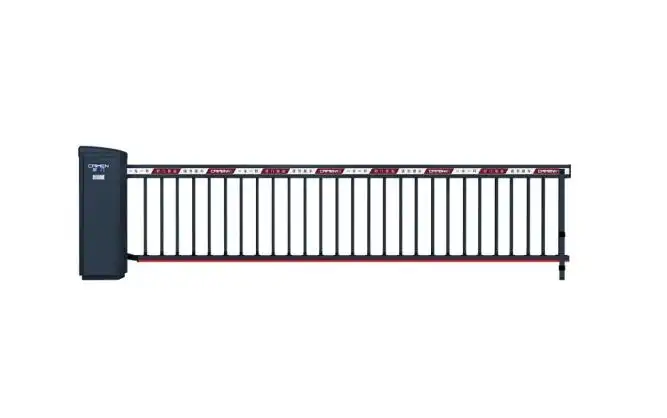

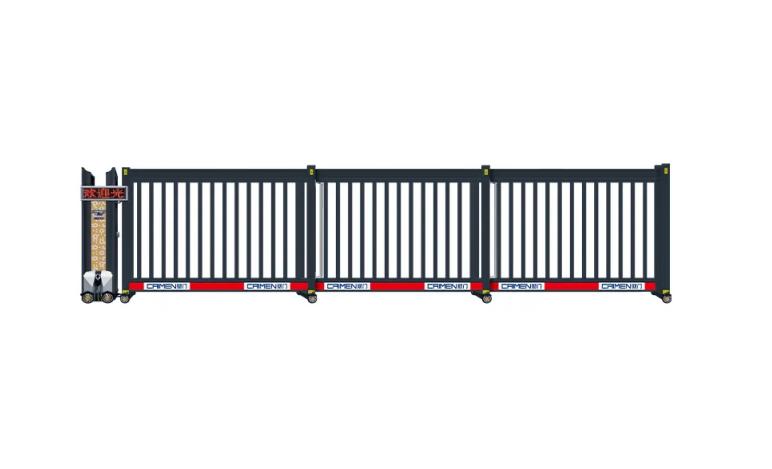

Introducing the Telescopic Sliding Gate

Many sites need a wide clear opening but lack back-run space. Here, a Telescopic Sliding Gate solves the geometry while maintaining durability. It excels at schools, hospitals, villa driveways, side entrances, and compact commercial properties - anywhere every meter matters.

Flexible Structure And Adaptability. The segmented telescopic form can be tailored up to 14 meters in length and 1.6 meters in height (customizable). Sections connect via hinged or pulley-based systems to keep motion controlled and smooth. A 680 mm wide chassis increases stability and wind resistance, which directly reduces misalignment and wheel wear.

Durability From The Frame Outward. Frames use high-quality aluminum alloy with advanced coating for long-term oxidation resistance. A 220 V single motor with copper components offers stable torque and efficient heat dissipation, enabling reliable performance from −35 °C to normal ambient temperatures - useful for cold-region deployments where brittle failures are common.

Tracks, Guidance, And Rolling Gear. Choose one-piece molded all-aluminum tracks for lightweight durability, or solid galvanized steel tracks for heavy-duty sites. The guide card auto-adjusts up and down for steady travel. In trackless modes, magnetic scanning correction keeps the gate moving straight, reducing friction and extending wheel life. Newly upgraded nano-level wear-resistant large wheels with all-cast aluminum hubs combine smooth rolling with a refined appearance.

Safety That Works With The Mechanics. CAIMEN integrates intelligent protection on top of robust hardware:

• Anti-pinch pressure sensing stops or reverses on contact.

• Infrared anti-collision detects obstacles during closing and commands an automatic return.

• Infrared anti-climbing triggers an alarm shortly after closure if activity is detected at the top beam.

• Emergency-stop instantly cuts power in urgent situations.

• Independent leakage-protection improves electrical safety.

Protected Power Transmission. The power-supply transmission uses a chain, stainless steel wire brackets (one-piece molded, 1500 °C), nylon protection wheels, and 99.99% oxygen-free pure copper 3-core wire. The combination resists disconnection, abrasion, and leakage - three silent killers of gate uptime.

Smart, Efficient Control. CAIMEN's 10th-generation digital integrated control system runs 5x faster than the previous iteration and connects easily to smart devices for automation, scheduling, and remote checks. A front display provides status via angled scrolling messages. Frequency conversion, soft start, and soft brake minimize mechanical shock, reduce peak loads, and lengthen the life of motors, wheels, and tracks.

CAIMEN's Selection Playbook And Practical Scenarios

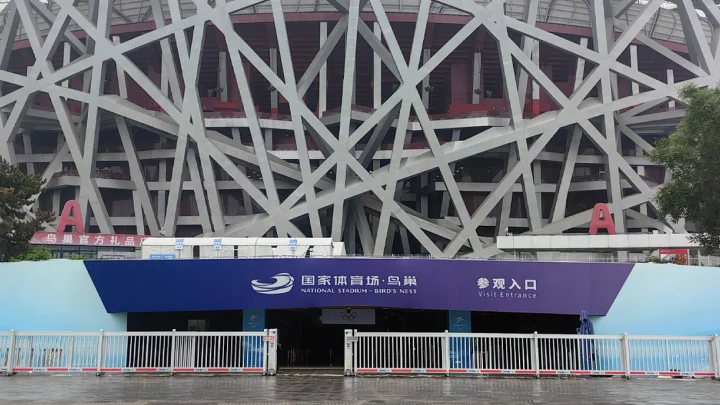

CAIMEN's rule is practical: match the material to the mission, then reinforce the interfaces that usually fail first. That is how the company extends real-world service life and lowers total cost of ownership for every Custom Sliding Gate.

✅ Scenario-Based Recommendations:

• Compact Urban Entrances: Aluminum alloy telescopic Custom Sliding Gate with molded aluminum track for quiet, low-wear operation.

• Heavy-Vehicle Logistics: Aluminum gate body with a galvanized steel track rated up to 120 t for axle loads - rigid track, lighter frame.

• High-Wind Corridors: Wide chassis (680 mm), wind-resistant hooks, and I-beam/aluminum rails to preserve alignment and reduce wheel edge loading.

• Cold Regions: Motors proven to −35 °C, frequency-conversion drives, and nano-grade wheels that resist brittleness.

Maintenance That Actually Reduces Cost. Because the structure is aluminum and coatings are stable, most sites need only light care: periodic checks of wheels and guides, quick track cleaning, sensor tests, and a fast look at cable brackets and nylon protection wheels. These small routines stretch service intervals and prevent surprise outages.

✅ Proof Points From Engineering

• Motor Housing: Precision die-cast aluminum alloy for strong heat dissipation and stable performance.

• Drive Behavior: High starting torque for frequent forward/reverse cycles; self-locking for positional security; manual clutch for manual release during outages.

• Seven Built-In Advantages: Frequency conversion, soft brake, soft start, high-temperature protection, motor self-locking, manual clutch, overload protection.

Why Aluminum Often Wins For Longevity. For most sites, the best answer is an aluminum alloy frame with advanced coating: it's light enough to spare the drivetrain, stiff enough to hold geometry, and resistant enough to fight corrosion. When loads are extreme, CAIMEN pairs aluminum bodies with galvanized steel tracks - a hybrid that balances corrosion control, structural strength, and energy efficiency.

✅ Selecting Your Custom Sliding Gate, Step-By-Step

- Define space constraints and opening width - confirm whether telescopic geometry is required.

- Map vehicle types, axle weights, wind exposure, and climate (salt, humidity, freeze-thaw).

- Choose frame material (aluminum baseline; steel track where loads dictate).

- Specify safety (anti-pinch, IR anti-collision/anti-climb, emergency stop, leakage protection).

- Finalize controls: frequency conversion, soft start/stop, and smart connectivity for remote oversight.

Call To Action - Build It To Last With CAIMEN

If you're planning a Custom Sliding Gate that must fit a tight footprint, resist harsh weather, and run year after year with minimal attention, talk to CAIMEN. Our engineers will match material, track, and control logic to your site conditions, provide a clear lifecycle cost view, and guide you from design to commissioning - so your gate opens smoothly, safely, and for a very long time.

FACEBOOK

FACEBOOK

TWITTER

TWITTER

LINKEDIN

LINKEDIN